Design and Engineering

Successful tooling projects start with creating a part design that meets a customer’s specifications. At HH, our engineering team has the ability to incorporate the necessary features conducive to good manufacturing processes for plastic injection molding, performing this task in a professional and confidential manner.

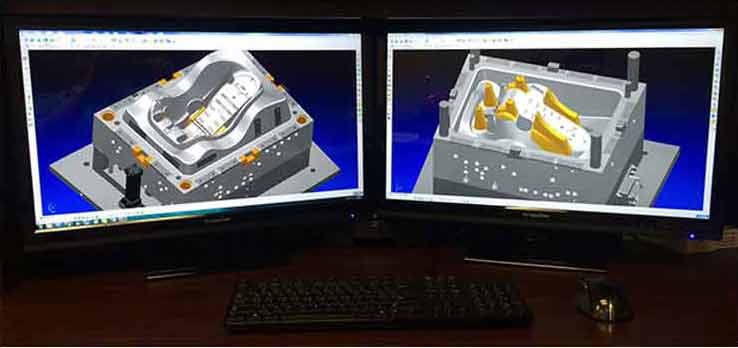

Experience combined with state of the art technology is one of the reasons HH makes a difference, and our molds show it. For all the molds we build, the following comprehensive engineering studies are performed by our tooling engineers:

• Mold Flow Analysis

• Draft analysis

• Wall section analysis

• Parting line development in conjunction with our customers

• Gating and Ejection location development in conjunction with our customers

• Multiple iterations of Mold flow studies

• Cooling optimization

• Preliminary mold design concepts

• Tool manufacturing strategy development for smoother tool validation process

• Full 3D mold design

• Detailed mold components (2D & 3D)

No. 11, Lougang Road, Bao'an District, Shenzhen, Guangdong, China. 518105

Tel: +86-755-23729206